PCR and Materials

PCR and Materials

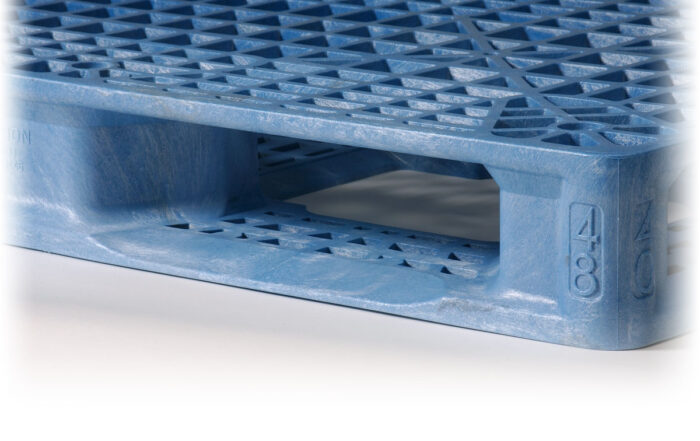

At OCS Products, we are dedicated to not only using PCR, post-industrial materials, and plastic regrind in our dunnage solutions, but also to leveraging our customers’ own waste streams as part of our sustainability efforts. By working closely with our clients, we can repurpose their plastic waste, transforming it into high-quality, reusable packaging materials. This closed-loop system reduces the demand for virgin plastics, decreases waste, and supports a circular economy. Our custom dunnage solutions are designed with sustainability in mind, using a combination of recycled content and regrind, all while maintaining durability and performance.

Financially, OCS is well-positioned to invest in further research and innovation in sustainable materials. We continue to explore new ways to integrate higher percentages of recycled content, both from our customers and other sources, into our product lines. Our commitment to expanding these initiatives allows us to help customers reduce their environmental impact while also maintaining cost efficiency. As we push the boundaries of sustainable manufacturing, we remain focused on delivering reliable solutions that benefit both the environment and your business operations.

OCS Products’ Commitment to PCR, Post-Industrial Materials, and Plastic Regrind:

- Increased Use of PCR Materials: We actively incorporate Post-Consumer Recycled (PCR) plastics into our dunnage solutions, reducing the demand for virgin plastics and supporting a circular economy.

- Post-Industrial Material Integration: OCS leverages post-industrial waste from manufacturing processes, ensuring that byproducts are reused, minimizing environmental impact.

- Plastic Regrind Utilization: We continuously test and refine the use of plastic regrind, optimizing its application in our products without compromising on strength or durability.

How OCS Continues Advancing Sustainable Material Usage:

- Ongoing Testing & Innovation: Our team rigorously tests the performance of recycled materials to ensure they meet the same quality standards as new materials while offering sustainability benefits.

- Custom Solutions: We develop tailored dunnage solutions that maximize the use of PCR, post-industrial materials, and plastic regrind, reducing reliance on new plastic production.

- Commitment to R&D: OCS invests in research and development to enhance the percentage of recycled content in our products, pushing the boundaries of what’s possible with sustainable materials.

- Sustainability Focus: We remain committed to reducing plastic waste by continuously improving the use of recycled content across our product lines, helping customers meet their sustainability goals.

From Our Blog

The Latest Supply Chain News

Have Used or Excess Pallets & Dunnage for Sale? We Buy it!

OCS Products: We’re Buying Used Plastic Pallets and More Across North America! At OCS

Tini Naturals: Redefining Personal Care with Reduced Plastic Packaging

Tini Naturals: Redefining Personal Care with Reduced Plastic Packaging In the journey toward sustainability,

FM Approved Plastic Pallets: What you need to know

The Importance of FM Approval for Plastic Pallets: What You Need to Know In